In the course of our work, Food & Beverage manufacturing executives and investors frequently refer to the strong score they received on their most recent SQF or BRC Food Safety Audit as evidence of the strength of their quality systems.

Yet in the last year alone, four multi-billion-dollar food manufacturers have closed a manufacturing facility, either temporarily or permanently, due to product recalls that exposed significant weaknesses in their quality systems and practices.

- Hormel: ~6 month shutdown of its Planters nut facility in Suffolk, Virginia following listeria contamination

- Treehouse Foods: temporary closure of its Cambridge, Maryland broth plant following recall in 2023

- Pepsico: permanent closure of its Danville, Illinois plant following salmonella recalls in December 2023 and January 2024 exposed repeated quality violations at the facility

- Boar’s Head: permanent closure of its Jarratt, Virginia deli meat plant following listeria contamination that led to multiple deaths and dozens of hospitalizations; USDA investigators found that the plant had ‘inadequate controls’ in place to prevent the spread of the bacteria

How reliable are audit results?

These incidents, which cost their owners millions of dollars in expenses and lost revenue and potentially impacted consumer trust in their products, raise important questions for manufacturers and investors regarding the reliability of SQF and BRC audit results as a measure of a manufacturer’s food safety risk.

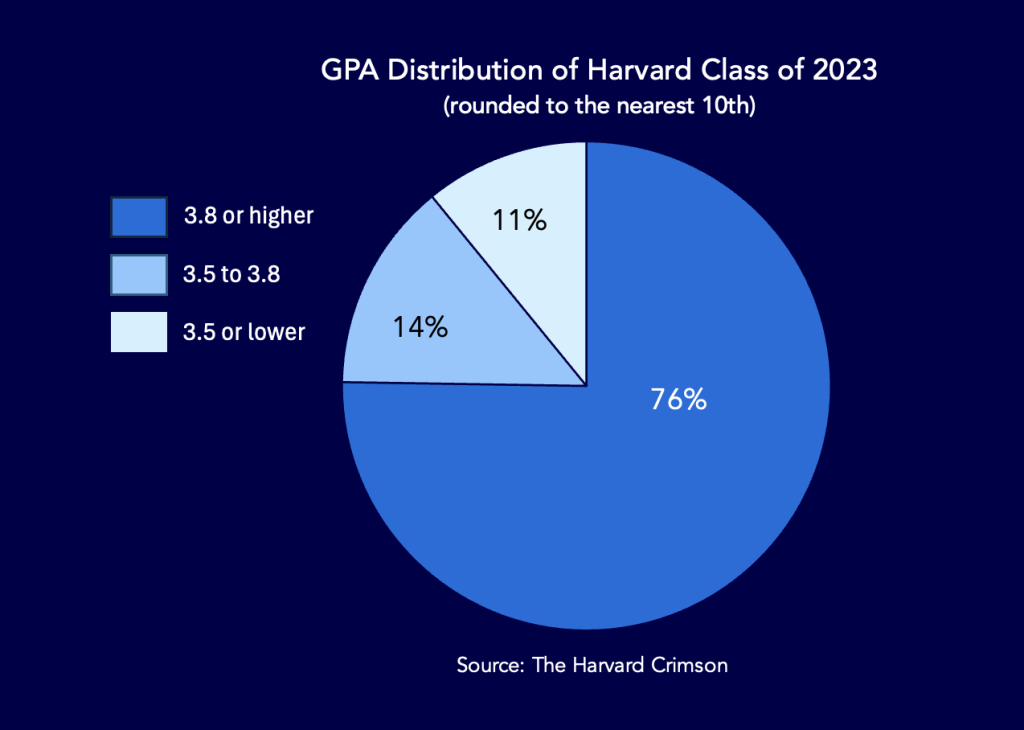

In July, Saphineia Insights published Everyone Gets an ‘A’ – Lessons for Food & Beverage Manufacturers and Investors. In it, we referenced “Grade Inflation Makes A the New C,” a December 2023 Wall Street Journal article which cited an anonymous survey by The Harvard Crimson as evidence of secular grade inflation in U.S. higher education. According to The Harvard Crimson’s most recent such survey, ~76% of Harvard’s 2023 graduates told the Crimson that their GPA was 3.8 or higher, up from just 54% in 2020. Just 11% of 2023 graduates said their GPA was 3.5 or below!

Grade inflation arguably exists in Food & Beverage manufacturing too

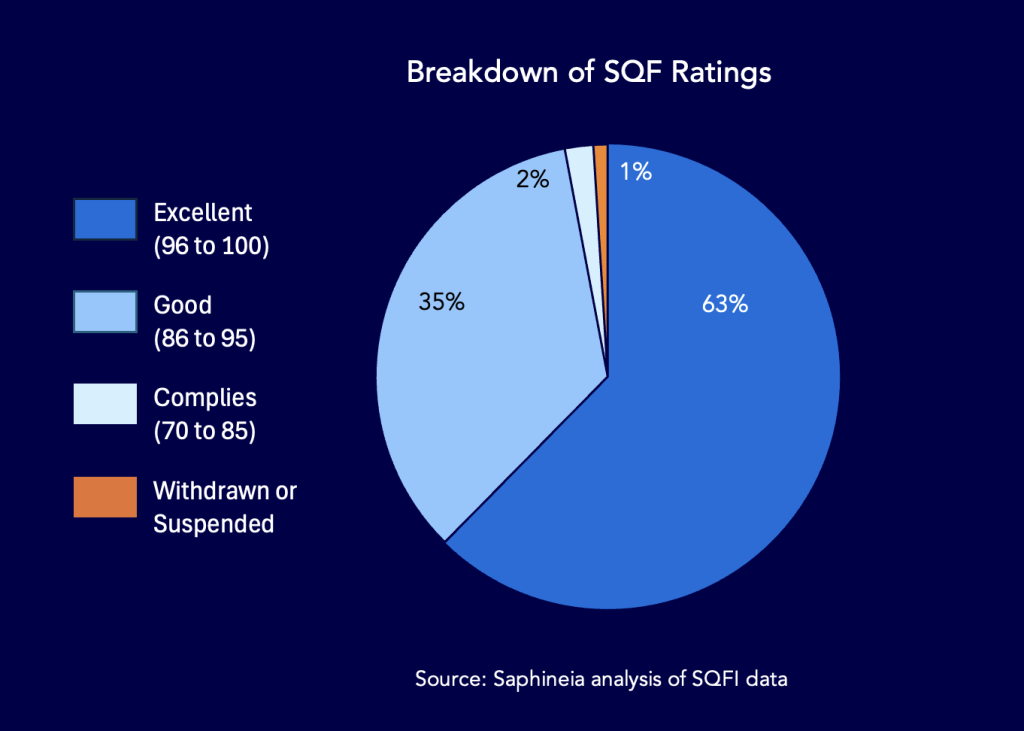

Saphineia recently studied the SQF ratings of 9,129 facilities in the United States and Canada. Based on our analysis, a whopping 98% of facilities received either an Excellent (scored 96 to 100) or a Good (scored 86 to 95) score on their most recent SQF audit. Just 2% failed or had their certifications withdrawn or suspended.

While these numbers did not surprise us, they were nevertheless a stark reminder that SQF scores should not be relied on as an accurate representation of the strength of a Food & Beverage manufacturer’s quality & food safety systems. In fact, since the SQF reduced the negative impact of a ‘major non-conformance’ from a 10-point deduction to a 5-point deduction, a facility can have six “Major” non-conformities and still pass their annual audit!

Implications for Manufacturers, Investors & Lenders

For senior executives overseeing manufacturing operations, the recent incidents at Pepsico, Hormel, Treehouse and Boar’s Head are an important warning of the dangers of relying on the latest SQF score as the definitive representation of the adequacy of their company’s quality systems (or those of its suppliers). Further, these incidents can serve as a valuable reminder to your organization that your plant’s annual SQF or BRC audit should not be viewed as a once-a-year check the box activity – after all, quality & food safety represents your ‘license to drive’ and is a 24/7 job. For this reason, just like human beings routinely undergo an annual physical, we recommend that manufacturers at least annually perform their own deep dive of their Q&FS practices over and beyond their work in preparing for their SQF or BRC audit (or retain a 3rd party to do this review).

For investors and lenders, the recent high-profile incidents highlight the importance of doing your own work and reaching your own conclusions regarding a manufacturer’s quality systems – i.e., in the same way you wouldn’t make an investment or loan based solely on a target’s or borrower’s financial forecast, we recommend doing your own diligence when it comes to quality & food safety.