Recently, my 91-year-old father fell, broke his hip and required surgery, necessitating long hospital and rehabilitation stays.

The day after surgery, my mom and I were in his hospital room when a nurse came in and said, “Sir, we need to do an EEG; I am going to attach 28 discs to your scalp.”

I wondered, “If he broke his hip, why would they need to attach electrodes to his head for an EEG? Did they see something during surgery?” Thankfully, I asked the nurse, “Are you sure you have the right patient?” Sure enough, she checked her paperwork and his wristband, and she was in the wrong room!

The next day, we were startled by a blaring announcement over the hospital loudspeaker, “AMBER ALERT, AMBER ALERT: 85-YEAR-OLD WOMAN MISSING; LAST SEEN IN THE SMITH WING, WEARING YELLOW PANTS; NOT AN ABDUCTION.” I don’t know if they ever found her – I sure hope so – but clearly, that was not supposed to happen!

One week later, on the second night of my dad’s rehab stay, a nurse came in with his nighttime pills. Fortunately, my dad had his wits about him, and realized that they were not his pills!

Lessons for Food & Beverage Manufacturers

Lesson #1: Humans make mistakes

What do these healthcare scares have to do with Food & Beverage manufacturing? My dad’s hospital and rehab stays highlight that mistakes happen when human beings are doing the work, whether that’s in a hospital or a manufacturing plant.

Lesson #2: There are hundreds of fail points in manufacturing

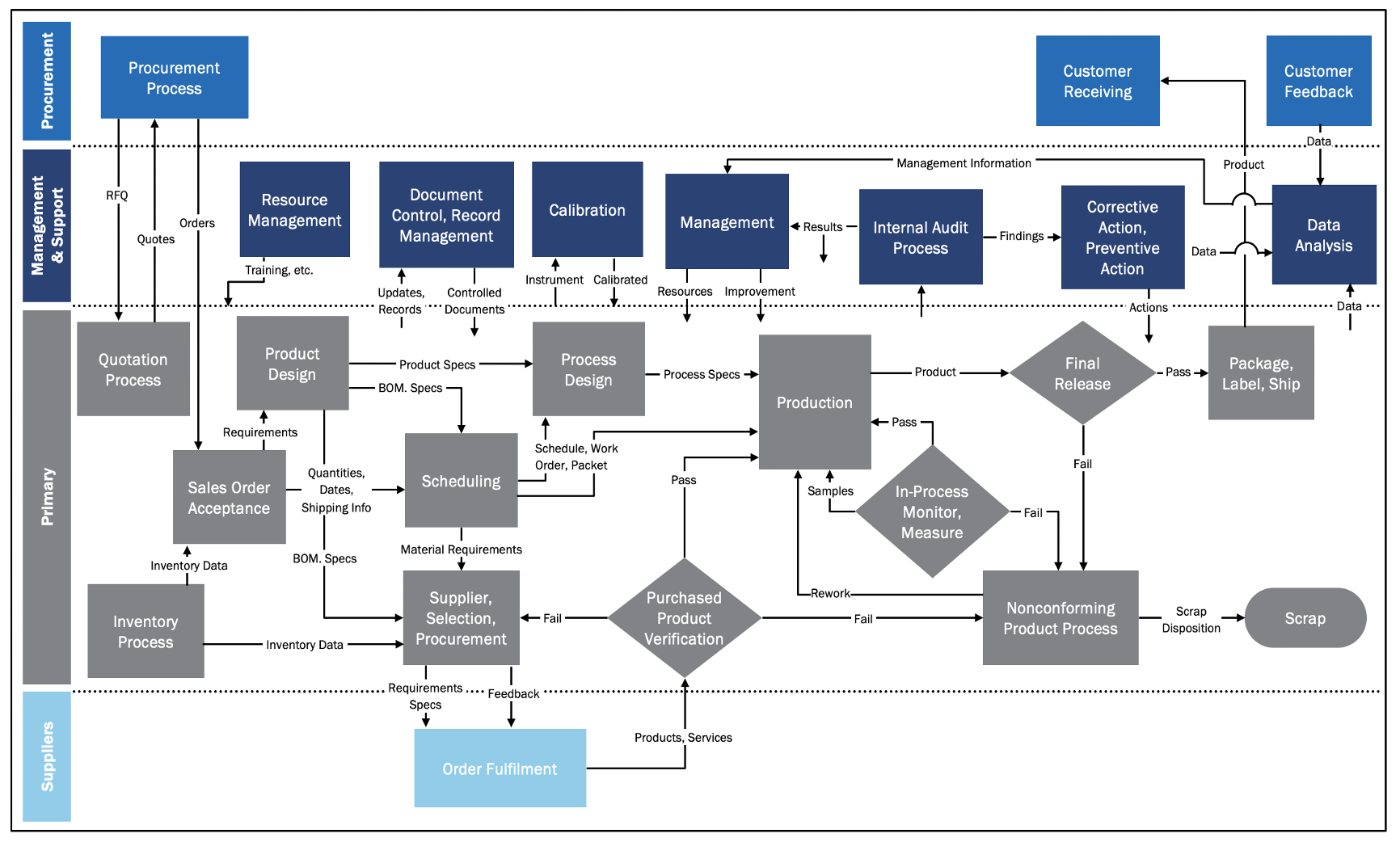

Certainly, the risks are generally lower outside of the healthcare context, but food safety risks and occupational safety hazards are very real. Moreover, the fact remains that there are hundreds of potential fail points in a manufacturing business – and as the below manufacturing process map highlights, it takes significant coordination to consistently and correctly perform the numerous steps required to produce a safe, quality, food product efficiently and cost-effectively.

Lesson #3: Strong business processes reduce costly errors

Every time an error is made on the shop floor, your business is incurring unnecessary cost and/or taking on unnecessary risk. Leading Food & Beverage manufacturers understand this, so they rely on strong business processes to reduce the risk of costly errors. In our experience, however, middle market manufacturers often do not. Rather, they spend much of their day in fire-fighting mode, responding to problems that could have been avoided with stronger processes.

Do any of these challenges sound familiar?

- Last minute schedule changes

- Having to do re-work

- High scrap levels

- Expired inventory

- Large inventory write-offs

- Too many changeovers

- Poor equipment reliability

- High employee turnover

- Off-spec product received from suppliers

What can you do to reduce these risks?

In our last research note, The Dangers of Relying on Tribal Knowledge (May 2024), we referenced how leading Food & Beverage manufacturers maintain documented operational processes and work systems to reduce the cost and disruption associated with employee turnover. Importantly, these processes and work systems also decrease the likelihood of human error, which reduces risk and variability in shop-floor performance, thereby improving gross margins.

What does it take for middle market manufacturers to obtain the same benefits?

- DOCUMENT your processes

- TRAIN your shop-floor employees on them

- Then AUDIT these processes regularly for compliance and to be sure they are up to date

Certainly, doing so isn’t easy, but it will reduce business risk and increase your margins.