Relying on tribal knowledge can be dangerous: A Real-Life manufacturing nightmare

The events described below are true. Names have been changed to protect the confidentiality of those involved.

Imagine you run a profitable condiment manufacturer. Your business is growing 25% annually, driven by demand for your company’s innovative R&D capabilities.

Then, one day, several longstanding members of your kitchen staff quit. Suddenly, instead of ~95% of your batches meeting your quality specifications on the first pass, your ‘right first time’ percentage falls immediately to 70%. Testing failures vary — wrong color, wrong pH level, failed emulsifications, etc.

Your plant’s daily output drops by ~25%; late orders begin piling up. Virtually overnight, your once profitable manufacturing business begins losing money, as you’re paying employees to stand around waiting for product from the kitchen and you are forced to dump valuable raw materials for ‘bad batches’ that can’t be fixed. Meanwhile, your sales, logistics and customer service teams are scrambling to adjust schedules, communicate with and placate customers about pending delays.

As you dig into what’s happening, you learn that your new kitchen employees are unable to follow the mixing instructions for your ~250 SKUs because they were not written clearly. This hadn’t been an issue previously because your kitchen leads had worked for your company for decades and ‘knew’ what they needed to do.

With your production and packaging departments frequently at a standstill, you need to fix it, fast. Unfortunately, short of getting these employees to return – which you try to accomplish, unsuccessfully – you are left with no choice but to re-write, from scratch, ~250 recipes, AND then train your new kitchen staff on the new, clearer instructions. The good news: the project to re-write the recipes was successful and your RFT% returned to 95%. The bad news: it took nearly 3 months, cost you ~$2.25mn in a combination of wasted labor and lost profit, and negatively impacted your customer relationships and your in-stock position at retail. In the meantime, you breached a debt covenant and were forced into an emergency preferred equity raise to placate your bank lender. You survive, but the crisis highlighted your business’s reliance on tribal knowledge.

This can happen to you

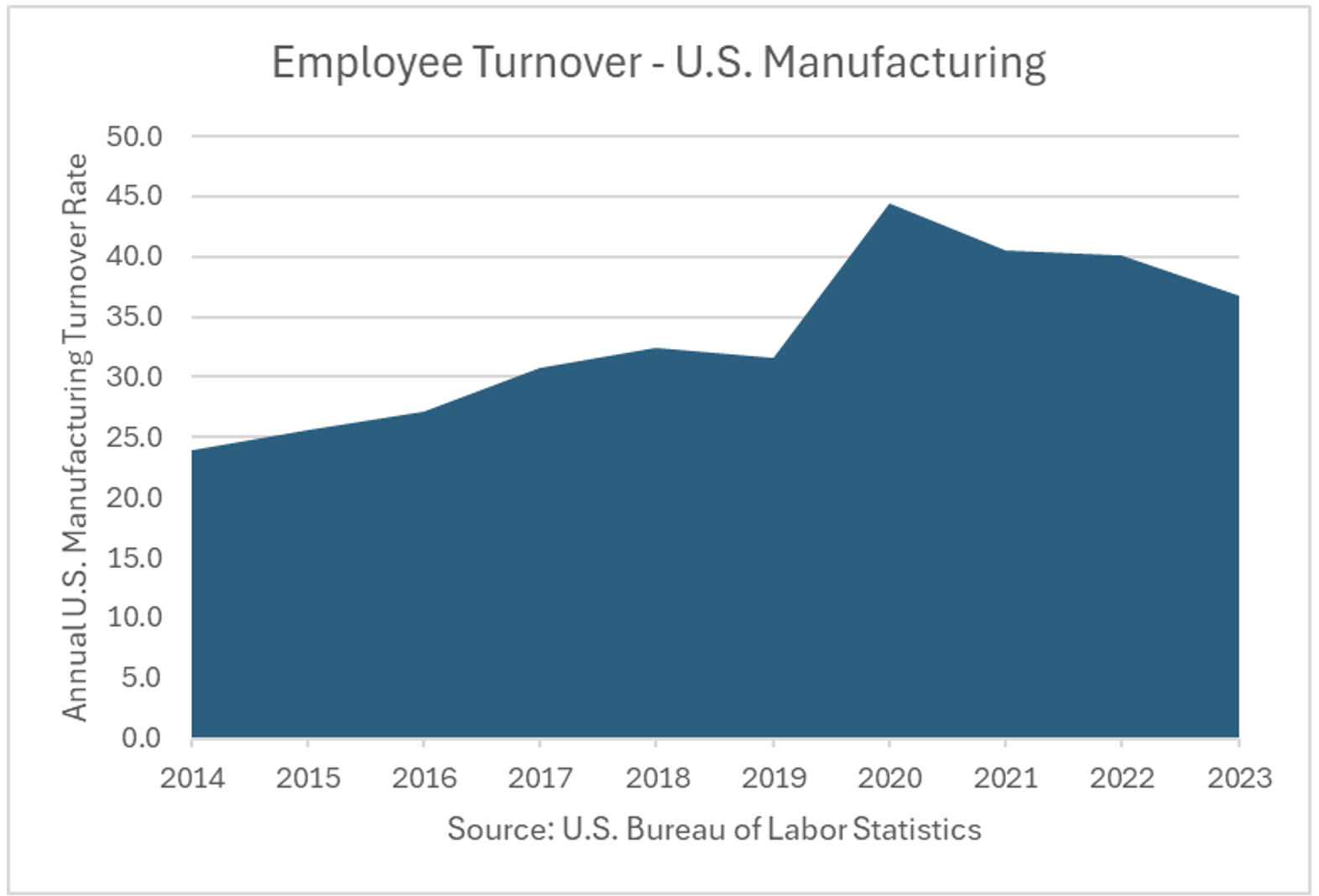

Since 2014, employee turnover rates in U.S. manufacturing have increased by over 50%!

While the situation has improved since the peak COVID years, the fact that over 1/3rd of manufacturers’ employee base departed in 2023 highlights the significant risk associated with over-reliance on tribal knowledge. Not to mention that turn over rates among hourly employees tends to be higher than the overall rates. In Saphineia’s work with middle market manufacturers, we’ve seen turnover rates well over 100% in certain cases and situations where manufacturers have half their shop-floor staff with less than one year on the job!

What can you do to reduce these risks?

Leading Food & Beverage manufacturers typically maintain documented operational processes and work systems to reduce the disruptions associated with employee turnover, improve the effectiveness with which they onboard new employees, and maintain consistent operational performance. Conversely, middle market manufacturers often rely on unwritten knowledge that exists only in the minds and knowledge of just a few individuals. As such, they are exposed to nightmare scenarios like what this condiment manufacturer experienced and generally lack the efficiency or consistency in operational performance they could achieve.

Fortunately, there’s no reason a middle market manufacturer cannot greatly reduce the risks associated with employee turnover and accelerate the rate at which new employees become proficient in their roles, while improving their overall performance. What does it take? Document and train your shop-floor employees on your work processes … and then audit them regularly for compliance and to be sure they are up to date. Certainly, doing so isn’t easy, but it sure beats the alternative.